Aluminium Gravity Die Casting

GS Engineering possesses significant expertise in aluminum gravity die casting, underpinned by a comprehensive and fully equipped production facility. We proudly serve the top echelons of the automotive industry in India, providing them with consistently high-quality and robust castings. Our dedication to stringent quality control measures throughout the casting process has established our reputation for delivering durable and reliable components that meet the exacting demands of the automotive sector.

Facility of GSE GDC Plant

- GDC machine – 4 nos 2nos(die mounting bead size 1000 ꓫ 800)with bottom core assembly support, 2nos of GDC m/c bead size 800 ꓫ 400

- Centralizes melting furnace -1 nos (500kg/92kw)capacity

- Melting cum holding furnace-3nos (500kg/72kw)capacity

- Degassing machine

- Vacuum machine

- Spectrometer

- Brinell Hardness Tester -1nos(capacity 3000kgf)

- Microscope

- Vaccum machine

- Sand testing Equipment(HTS, Sieve shaker, GC/LOI,S Hardness )

- T 6 Heat treatment (capacity 1500kg)

- Decoring machine – 1nos

- Vertical shot blasting Machine

- Hight Gauge digital & mechanical ,Verner caliper, surface tester, radius gauge, bevel protector and other Equipment

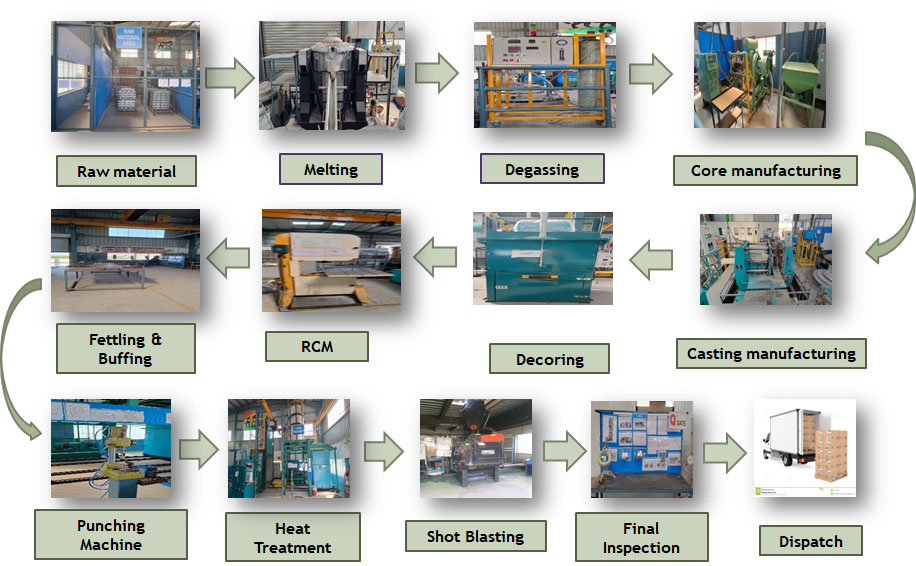

Process Flow

Planning & Strategy

Effective planning and strategy are essential for successful and efficient aluminum gravity die casting operations. Here’s a breakdown of key areas to consider:

- Part Design and Castability Analysis

- Tooling Design and Manufacturing

- Material Selection for Dies

- Process Parameter Optimization

- Material Handling and Automation

- Quality Control and Inspection

We are always ready to help you and answer your questions

Our Services

Aluminium

Gravity Die

Casting Foundry